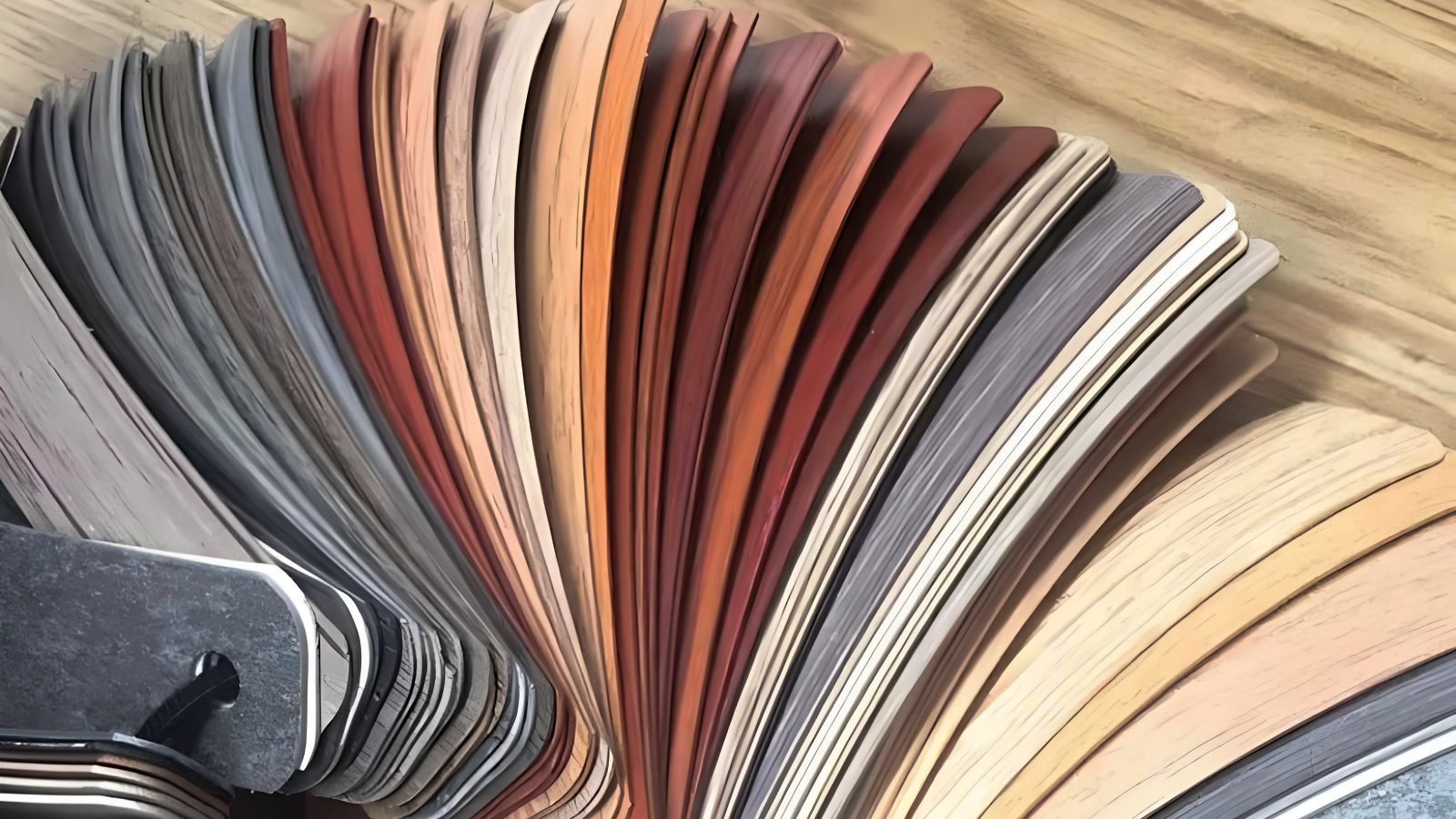

In furniture manufacturing, edge banding plays a crucial role in enhancing both the durability and aesthetics of furniture. Among various materials, PVC edge banding is the most widely used in the global market. With its competitive pricing, mature supply chain, and extensive customization options, China has become the preferred destination for furniture manufacturers and edge banding traders worldwide seeking cost-effective PVC edge banding solutions.

However, with such a vast number of PVC edge banding suppliers available, avoiding common pitfalls, identifying reliable partners, and securing favorable deals can be challenging. successfully importing PVC edge banding from China therefore requires careful supplier evaluation and strategic planning.

At Shengmei Edge Banding Factory, a Chinese manufacturer with over 15 years of experience in the edge banding industry, we share five key tips for sourcing PVC edge banding from China — including how to verify suppliers, understand minimum order quantities (MOQ), determine packaging methods, clarify lead times, and build long-term partnerships. by following these insights, you can efficiently and confidently source high-quality PVC edge banding from China.

Tip 1: Thoroughly Verify the Supplier

Before placing an order, make sure your edge banding supplier is a genuine manufacturer, not merely a trading company. Proper verification is essential to ensure they possess the required qualifications and production capabilities. You can evaluate this through the following key steps:

1. Verify Business Qualifications and Professional Certifications

Business License: Request the factory’s official business registration certificate. Confirm that its business scope explicitly includes manufacturing and selling edge banding or plastic products, rather than just trading activities.

Factory Photos and Videos: Ask for a recent factory video along with photos of the production workshop, raw material storage area, and finished goods warehouse. Whenever possible, arrange a live video inspection or hire a third-party inspection agency to verify authenticity.

Assess Production Capacity: Inquire about the number and types of extrusion lines, printing machines, and color-matching systems to confirm whether the factory can meet your production requirements.

Check Product Quality Certifications: Request copies of relevant international or industry certifications such as ISO 9001 Quality Management System and SGS test reports to ensure compliance with global standards.

Review Past Cooperation Cases: Ask whether the supplier has successfully worked with clients in your country or region. Factories with prior international experience usually have a better understanding of local consumer preferences and market trends, which helps ensure smoother cooperation and product suitability.

2. Request Samples for Product Testing

Before placing a bulk order, it’s highly recommended to request product samples for testing. Pay special attention to the toughness, color consistency, heat resistance, aging resistance, and compatibility of the PVC edge banding with your specific board materials.

You can also observe the sample packaging quality, as it often serves as an indirect indicator of the factory’s attention to detail and product commitment.

Tip: Reliable PVC edge banding manufacturers in China are primarily located in Guangdong, Zhejiang, and Jiangsu—regions known for their well-developed industrial bases, advanced production equipment, and mature supply chains.

Tip 2: Understand the Minimum Order Quantity (MOQ)

The Minimum Order Quantity (MOQ) is a critical factor in the procurement process, as it directly affects both your cost structure and inventory management. From the manufacturer’s perspective, the MOQ is typically determined by factors such as raw material purchasing costs, production line setup expenses, and overall production efficiency.

For standard colors and sizes of edge banding, many factories offer lower MOQs, typically around 500–1000 meters per color.

However, for customized designs—such as special colors, wood grains, gloss levels, or embossed textures—the MOQ may increase to 3000–5000 meters.

MOQ Negotiation Tips

Propose a trial order: If the supplier’s MOQ exceeds your expectations, suggest starting with a smaller trial order and committing to larger quantities in future orders.

Consolidate color orders: Combine multiple popular colors or sizes of edge banding into a single order to reach the total MOQ, rather than meeting the MOQ for each color separately.

Show long-term intent: Express your interest in establishing a long-term partnership and your plan for larger future orders. This often encourages suppliers to flexibly adjust or reduce the MOQ for initial cooperation.

Tip 3: Determine the Packaging Method

The packaging of your PVC edge banding plays a crucial role in ensuring that your products arrive safely and in perfect condition. Proper packaging not only protects the goods during long-distance transportation but also helps reduce ocean or air freight costs.

Common Packaging Options

Standard Export Packaging: Typically supplied in 100–200 meter rolls, sealed with PE film, and packed in cartons or woven bags.

Customized Packaging: You can request that your brand logo, barcode, and product specifications be printed on the carton to enhance your brand recognition and professional image.

Palletized Shipping: Recommended for large-volume shipments to prevent product deformation during ocean transport and to improve overall handling efficiency.

Key Points When Discussing Packaging with Suppliers

Clarify all requirements: When inquiring or placing an order, confirm every packaging detail with your supplier. Ask questions such as: “Is pallet packaging included?”, “What is the bursting strength of the carton?”, “Can you provide photos of the packaging?”.

Before production begins, make sure all packaging specifications are clearly stated on the pro forma invoice or order confirmation.

Balance protection and cost: Overly simple packaging can lead to damage during transport, while excessive packaging can increase costs and freight charges (since ocean freight is often billed by volume). Discuss with your edge banding supplier to determine the most cost-effective and protective packaging solution.

Tip 4: Clearly Define Delivery Timelines

Delivery timelines are a critical part of procurement planning. Poor timeline management can easily lead to production delays, inventory shortages, or missed shipment schedules. in China, the average production lead time for PVC edge banding is usually 7–15 days, depending on order quantity and whether the product is custom-made. to ensure reliable and on-time delivery, follow these best practices:

1. Request a realistic delivery schedule

Ask your edge banding supplier to provide a delivery date based on their current production workload, not just the fastest possible timeline.

2. Confirm shipping terms (Incoterms)

Clarify responsibilities and cost coverage by confirming whether your order follows FOB, CIF, or EXW terms.

3. Allow a reasonable buffer

Always include an additional 10–15 days of buffer time in your schedule to accommodate potential production or shipping delays.

4. Define penalties for delays

Clearly specify penalties or liability terms for late delivery in your purchase contract. This helps ensure the supplier prioritizes your order and maintains accountability.

5. Request progress updates

Ask your supplier to provide production updates and photos at key stages — such as raw material arrival, production start, 50% completion, and before packaging. This allows you to identify potential issues early and make timely adjustments.

Tip 5: Build a Long-Term Partnership

Once you’ve established a strong, long-term partnership with your Chinese edge banding supplier, you can expect numerous benefits — including better pricing, faster sample development, consistent product quality, and more proactive communication regarding new color trends and material innovations.

A stable partnership also fosters mutual trust, enabling both sides to collaborate more efficiently on production planning, quality improvements, and market expansion.

Successfully sourcing PVC edge banding from Chinese manufacturers requires both industry knowledge and careful planning. By following these five steps — verifying suppliers, understanding minimum order quantities (MOQ), determining packaging methods, clarifying lead times, and building long-term relationships — you can achieve competitive pricing, stable product quality, and a reliable supply chain.

Act now! Apply these sourcing strategies and contact us today to request PVC edge banding samples or a custom quotation tailored to your needs.