Edge banding is essential in furniture manufacturing and edge banding traders. Whether for wardrobes, cabinets, office furniture, children’s furniture, or outdoor pieces, edge banding enhances aesthetic appeal and protects surfaces from moisture and scratches, thereby prolonging their lifespan. For manufacturers and edge banding traders, selecting the appropriate edge banding material is a key consideration during procurement. Shengmei Edge Banding Manufacturer has compiled frequently asked questions (FAQs) on edge banding procurement to help you quickly grasp key purchasing priorities.

1. What is edge banding?

Edge banding is a decorative and protective material used to seal the edges of furniture panels, providing a decorative finish and added protection. It typically wraps the cut surfaces of man-made panels (such as medium-density fiberboard, particleboard, and plywood), providing both aesthetic appeal and decorative benefits while also protecting against moisture and cracking, and enhancing durability. It is an essential component in the manufacture of panel furniture (such as wardrobes, cabinets, desks, and doors).

2. What are the common materials for edge banding?

Common edge banding materials on the market include:

PVC edge banding:

Made primarily from polyvinyl chloride (PVC), this edge banding offers affordability and a wide variety of colors, making it a popular choice for panel furniture.

ABS edge banding:

Made primarily from acrylonitrile-butadiene-styrene copolymer, it offers excellent environmental performance and strong impact resistance, making it commonly used in furniture requiring high environmental and quality standards.

PP edge banding:

edge banding made of polypropylene as the main raw material. The material is light in weight, environmentally friendly, and has good toughness. It is often used in furniture that pursues environmental protection and a modern feel.

Wood edge banding:

Edge banding made of natural veneer or technical veneer as the main raw material, which has both solid wood texture and decorative properties, and is often used in high-end furniture.

Acrylic edge banding:

Edge banding made of acrylic as the main raw material, with high transparency and bright colors, is mostly used in modern-style furniture and high-end custom furniture.

Melamine edge banding:

edge banding made of decorative paper impregnated with melamine resin as the main raw material. It has a low cost and a strong decorative effect and is suitable for use in medium and low-end furniture.

Purchasers can choose edge banding of different materials based on furniture positioning, environmental protection requirements, physical properties, and budget.

3. How do furniture manufacturers choose the right edge banding?

When choosing edge banding, furniture manufacturers need to consider factors such as furniture grade, board type, usage environment, cost, etc. They can judge and choose from the following aspects:

Furniture Grade:

Low- to mid-range furniture: PVC and melamine edge banding offer high cost-effectiveness, a variety of colors, and are suitable for mass production.

High-end furniture: ABS and PP edge banding are durable and environmentally friendly, suitable for those seeking quality and durability.

High-end custom furniture: Veneer or acrylic edge banding better meets high-end visual effects and texture requirements.

Specialty furniture: Metal (aluminum) edge banding can better enhance industrial or minimalist styles.

Board Type:

Edge banding is suitable for different materials, including particle board, medium-density fiberboard, eco-friendly board, and solid wood. For example:

Particle board/MDF/MDF: Commonly used edge bandings include PVC, ABS, PP, and melamine.

Solid wood or composite wood: Wooden edge banding is recommended. Acrylic can be used for a glossy finish if a natural look is desired.

Usage Environment:

Wet environments (kitchens, bathrooms): PVC and PP edge banding are water-resistant and better suited for moisture protection.

High-temperature or outdoor environments: PP and ABS edge banding offer excellent heat resistance and chemical stability.

Laboratory environments: PP and ABS edge banding offer excellent resistance to chemical solvents.

Cost:

For high-volume production: PVC or melamine edge banding is recommended due to its low cost and suitability for mid- to low-end furniture.

For high environmental requirements: ABS and PP edge banding offer excellent environmental performance and are reasonably priced, making them suitable for mid- to high-end furniture.

For high-end furniture: Veneer and acrylic edge banding enhance the quality and aesthetics of furniture, but are more expensive and suitable for high-end custom furniture.

For furniture manufacturers, choosing edge banding is a decision that balances cost, performance, and market positioning. For the ultimate in cost, choose PVC or melamine edge banding; for environmental protection and performance, choose PP or ABS edge banding; for the ultimate in appearance, choose acrylic or wood edge banding.

4. Can edge banding be customized?

Yes. Custom edge banding is a very common and established service in the furniture industry, especially for furniture manufacturers with distinctive branding, unique designs, or those targeting the high-end market. Custom edge banding is also a key way for edge banding factories to achieve product differentiation.

Custom edge banding services primarily cover the following levels, arranged from simple to complex:

1. Color and Texture Customization

This is the most common and fundamental customization requirement. When a furniture manufacturer develops a new panel finish (wood grain, stone grain, solid color, etc.), they need edge banding that perfectly matches it.

How it’s achieved: Suppliers will match the color and texture based on a panel sample or Pantone color card provided by the customer, producing edge banding with highly consistent color and texture. This is crucial for achieving a high-end, seamless, and consistent visual effect.

Applicable Materials: Edge banding made of materials such as PVC, ABS, and PP is well-suited for this type of customization because their surface finish is applied via printing or lamination, offering exceptional flexibility.

2. Custom Sizes

Standard edge banding comes in common thicknesses (between 0.3mm and 3mm) and widths (between 12mm and 60mm). If your furniture has a unique structure, custom sizes may be required. Therefore, the edge banding manufacturer must be able to customize the thickness and width of the panels.

3. Customized Physical Properties

For factories with edge banding R&D capabilities, we can customize the edge banding’s anti-friction properties, impact resistance, flexibility, weather resistance, and other properties based on the purchaser’s application requirements.

Therefore, edge banding is completely customizable and is an important means for edge banding manufacturers to enhance product competitiveness and brand recognition. From the simplest color and texture matching to size and complex physical properties, everything can be achieved according to the buyer’s needs.

5. What are the common specifications of edge banding?

Common edge banding widths include: 19mm, 22mm, 25mm, 28mm, 30mm, 35mm, 40mm, and 60mm.

The width must be selected based on the thickness of the board being edge-banded. Typically, the edge banding width should be slightly greater than the board thickness to ensure complete coverage.

Common edge banding thicknesses: 0.3mm–3.0mm

Thickness is a key indicator of edge banding quality, feel, and processability, and is typically measured in millimeters.

Ultra-thin edge banding: 0.3mm – 0.45mm

Application: Primarily used for manual edge banding or for cost-sensitive, low-end products. Extremely high requirements are placed on the smoothness of the board edges, as it offers limited hiding power.

Features: Lowest cost, but the edge feels hard after banding and offers average durability.

Conventional edge banding: 0.5mm – 0.8mm

Application: This is the most widely used specification. Most automatic edge banding machines use this thickness range. It strikes a good balance between cost, feel, and hiding power.

Features: This is the mainstream thickness in the furniture market, offering a high cost-performance ratio.

Thickened edge banding: 1.0mm – 3.0mm

Applications: 1.0mm – 1.5mm: Used in mid- to high-end furniture requiring a rounded, richer edge. 2.0mm – 3.0mm: Typically requires special glue and processing techniques and is used for thicker panels (such as countertops) or when achieving unique edge shapes.

Features: Provides a full, solid edge feel and excellent coverage, but at a higher cost.

Common edge banding lengths: 100m/roll, 200m/roll, 250m/roll, 300m/roll.

Most PVC, ABS, PP, and other edge banding materials used in automatic edge banding machines are supplied in rolls. 200m/roll is the most common industry standard, while 250m/roll and 300m/roll lengths reduce roll changes during production and improve efficiency.

6. How to choose the specifications of edge banding?

The specifications of the edge banding should be selected based on the thickness of the board, furniture positioning, cost, production equipment, etc. The specific process is as follows:

1. Choose the width based on the board thickness.

This is the most fundamental and objective factor. The golden rule is: edge banding width = board thickness + (2-3 mm). This extra 2-3 mm ensures the edge banding completely covers the board edge. After the edge banding machine completes the trimming process, a perfectly flat surface is left, preventing any gaps in the edge banding.

2. Choose thickness based on the furniture’s design and cost.

The thickness of the edge banding directly affects the feel, appearance, and durability of the finished furniture. Recommended thicknesses for budget-friendly products are 0.4mm-0.6mm, for mid- to high-end products are 0.8mm-1.0mm, and for high-end products or countertops are 1.5mm-2.0mm or higher.

3. Choose the length and thickness based on the edge banding equipment.

It’s important to determine if your edge banding machine has a minimum thickness requirement. Thin edge banding strips (e.g., under 0.4mm) may not be stably transported and processed on high-speed automatic edge banding machines. Common roll lengths for edge banding strips are 100, 200, 250, and 300 meters. 200 meters per roll is the most common. Longer rolls reduce roll changes and improve efficiency.

In short, edge banding with a thickness of 0.5mm-0.8mm, a width of 2-3mm thicker than the board, and a roll length of 200 meters is the most common and versatile specification on the market. When choosing the edge banding specification, please be sure to consider your own product requirements and production conditions.

7. Is edge banding environmentally friendly?

Edge banding itself can be environmentally friendly, but its environmental performance depends on the material and production process. Examples of more environmentally friendly edge banding include PP, ABS, and wood. Commonly, environmentally friendly edge banding includes PVC, melamine, and acrylic. Furniture manufacturers focused on environmentally friendly export standards (such as those targeting the European and American markets) are recommended to use ABS, PP, or veneer edge banding. For those prioritizing cost-effectiveness, PVC edge banding remains the mainstream choice.

8. What is the minimum order quantity (MOQ) for edge banding?

For regular, in-stock colors, edge banding suppliers typically allow small orders, ideal for traders or new customers to test. For custom colors or patterns, most edge banding manufacturers require a minimum order of 3,000–10,000 meters to ensure production efficiency and color stability.

9. How is the price of edge banding calculated?

It is calculated based on the material, specifications, process, color, and order quantity. Usually, manufacturers will calculate by the meter or kilogram, and then quote according to customer needs.

10. Will there be any quality issues with the edge banding?

Yes, edge banding is prone to quality problems during production and use if the production process or operating process is not up to standard. Generally, they are divided into two categories: production quality problems and use quality problems:

1. Production Quality Issues

Common issues encountered during the production process include color variations, inconsistent dimensions, surface defects, and insufficient toughness of the edge banding.

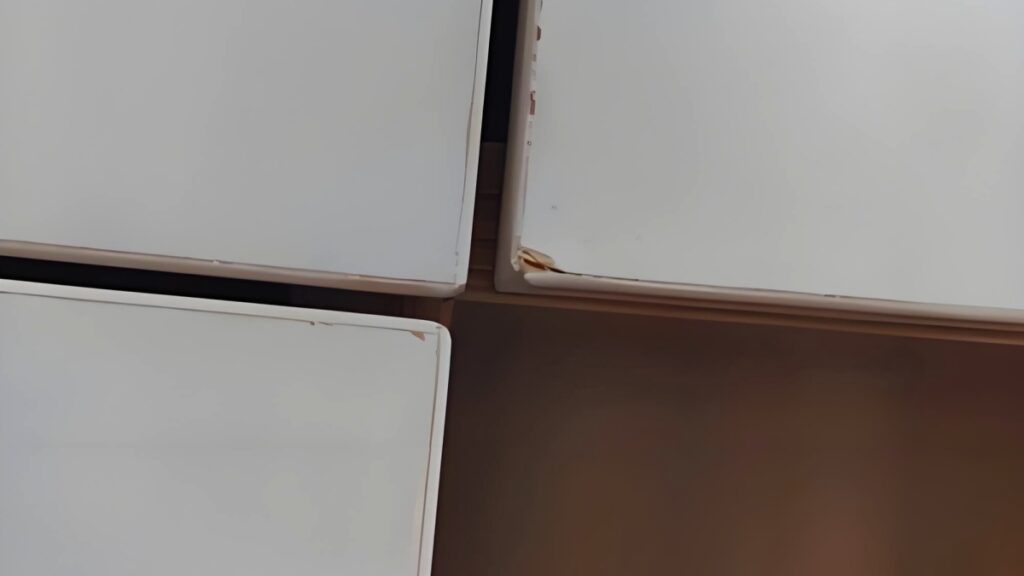

2. Quality Issues During Use

Common quality issues during use include: edge banding peeling, shrinkage, excessively thick glue lines, uneven trimming, and surface scratches.

11. Which edge banding machines are compatible with edge banding strips?

The compatibility between edge banding strips and edge banding machines is a key factor affecting edge banding quality and production efficiency. Simply put, compatibility mainly depends on the “material” and “shape” of the edge banding strips, as well as the “function” and “configuration” of the edge banding machine. The compatibility between common edge banding machine types and edge banding strips is as follows:

Manual Edge Banding Machine

Suitable for: Narrow PVC, ABS, and melamine edge banding (common width ≤ 60mm, thickness ≤ 1mm).

Features: Easy to operate, suitable for small furniture factories or individual workers.

Semi-automatic/Hand-Push Edge Banding Machine

Compatible with: PVC, ABS, and wooden edge banding with thicknesses between 0.4 and 2.0mm.

Features: While not very fast, it can handle small to medium-sized batches.

Fully Automatic Linear Edge Banding Machine (Hot-Selling Model)

Compatible with: Most PVC, ABS, PP, melamine, veneer, and acrylic edge banding strips.

Features: Automatic gluing, trimming, and polishing. Suitable for batch edge banding of furniture panels.

Curved/Odd-Shaped Edge Banding Machine

Compatible with: Flexible PVC, ABS, and melamine edge banding (generally ≤1.5mm thick).

Features: Primarily used for edge banding on tabletops, rounded, or irregularly shaped surfaces.

Laser Edge Banding Machine / Hot Air Edge Banding Machine

Compatible with: Specialized laser edge banding strips with a functional layer, eliminating the need for traditional hot melt adhesive.

Features: Seamless edge banding, a high-end finish.

For furniture manufacturers and edge banding traders, the most important considerations when purchasing edge banding include material selection, environmental performance, customization capabilities, specifications, price, MOQ, and quality consistency. Choosing an edge banding manufacturer with extensive experience, support for customization, and stable supply not only ensures the overall quality of the furniture but also gives companies a competitive edge in the market. If you are looking for a manufacturer of PVC, ABS, or PP edge banding, or custom edge banding, please contact Shengmei Edge Banding Manufacturer for more product information and quotes.