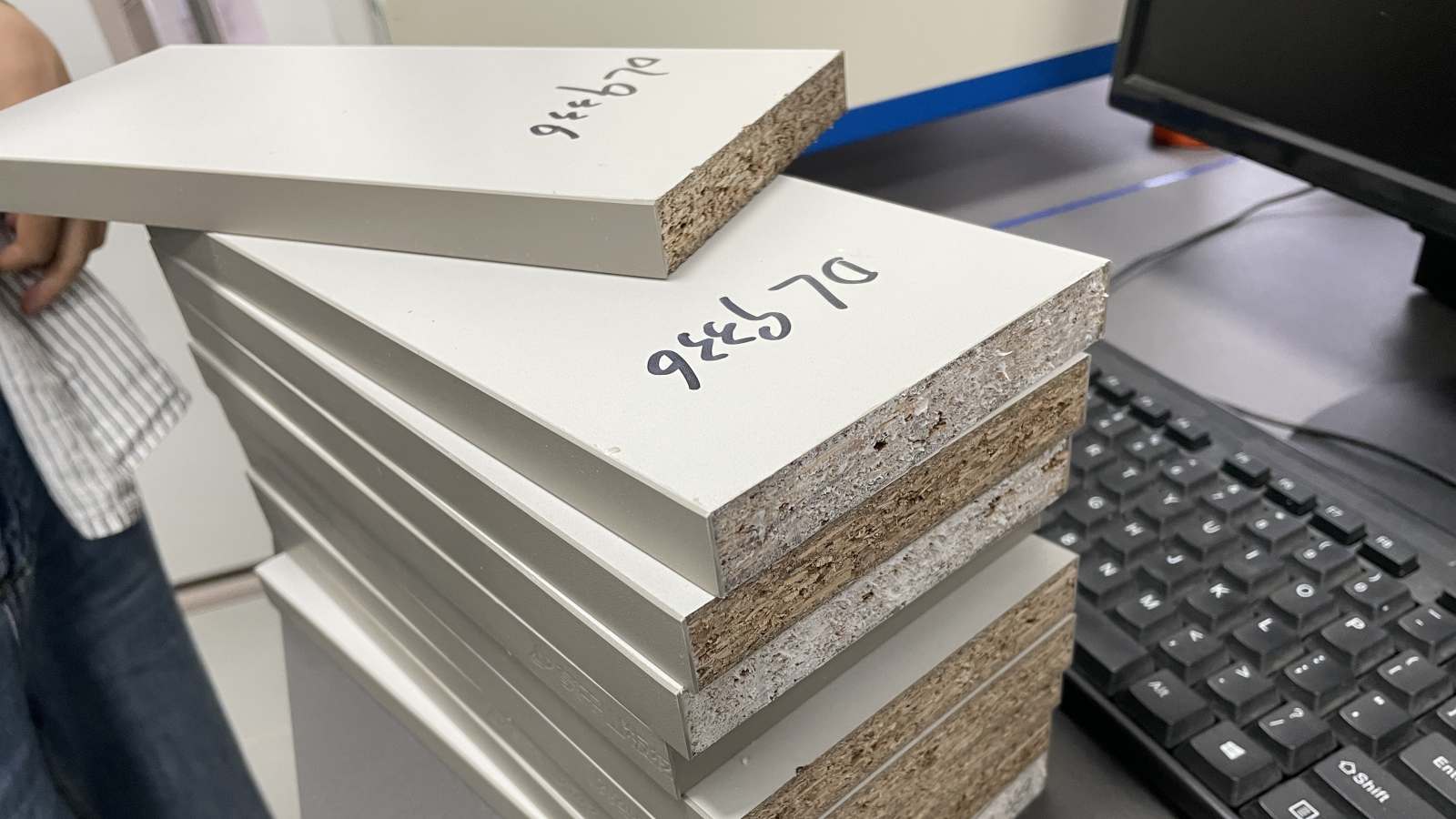

Particleboard is widely used in modern furniture manufacturing and interior decoration because of its cost-effectiveness, stability, and smooth surface. However, without proper edge protection, particleboard can easily absorb moisture, crack, or lose its structural strength over time.

Applying edge banding for particleboard effectively solves these issues. It not only provides durable protection and extends the lifespan of furniture, but also gives furniture pieces a clean, professional, and visually appealing finish.

For furniture manufacturers and edge banding suppliers, understanding the right type of edge banding for particleboard is crucial. In this article, we’ll explore why edge banding matters, the main types used for particleboard, and how to choose the best edge banding for your furniture production needs.

Why is edge banding necessary for particleboard?

Particleboard is a cost-effective and widely used material in panel furniture manufacturing, but its structure is relatively loose compared to medium-density fiberboard (MDF) or plywood, making it more prone to cracking and damage. That’s why applying edge banding to particleboard is an essential step in production. Here are the key benefits:

1. Moisture Protection — Extending Furniture Lifespan

The biggest drawback of particleboard is its tendency to swell or deform when exposed to moisture or humid environments. Applying edge banding tightly seals the cross-section of the board, preventing moisture absorption and greatly extending the durability and service life of the furniture.

2. Strengthened Edges — Improved Durability and Impact Resistance

Edge banding significantly enhances the edge strength of furniture, improving wear and impact resistance. It prevents cracking, chipping, and edge damage that can occur during daily use or transport, ensuring long-lasting quality.

3. Sealing Formaldehyde — Creating a Healthier Indoor Environment

During particleboard production, adhesives containing formaldehyde are often used. Applying edge banding helps seal in formaldehyde emissions, reducing their release into the air and making furniture safer and more eco-friendly.

4. Enhanced Appearance — Increasing Furniture Value

Edge banding creates a smooth, seamless finish that hides rough edges and matches the surface design of the panel. This not only improves the furniture’s aesthetic appeal but also enhances its overall market value and perceived quality.

What Types of Furniture Use Particleboard Edge Banding?

Because of its high cost performance, versatility, and customization potential, particleboard is one of the most popular materials used in panel furniture production. Applying edge banding is a key finishing process, ensuring both beauty and durability.

Common types of furniture that use particleboard edge banding include:

- Kitchen cabinets and wardrobes

- Shoe cabinets and TV stands

- Office desks and storage units

- Display cabinets and bookshelves

What Are the Best Edge Banding Options for Particleboard?

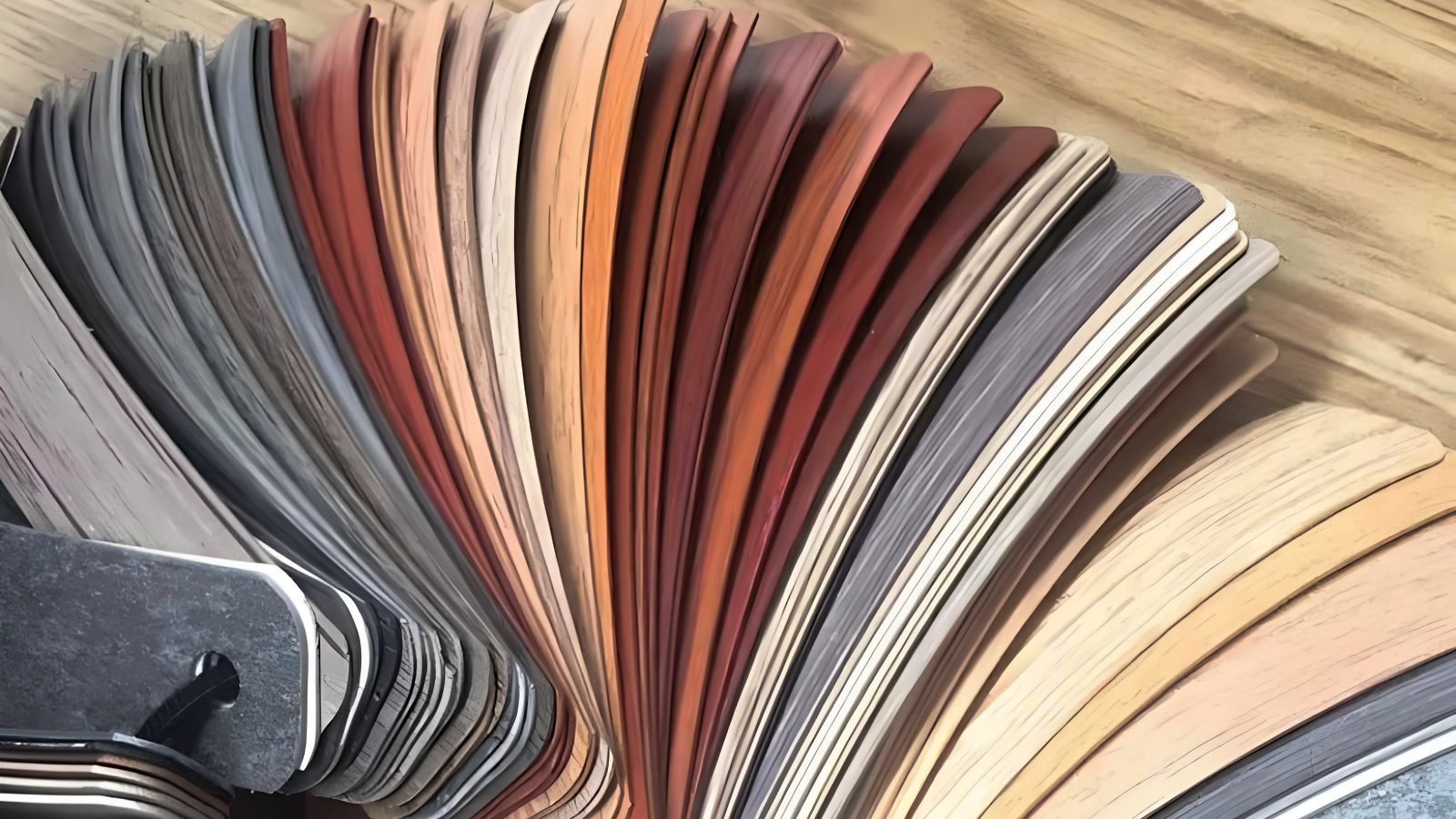

Choosing the right edge banding strips for particleboard is essential for achieving durability, aesthetics, and environmental performance. Based on materials and manufacturing processes, the most common types of particleboard edge banding available on the market include the following:

1. PVC Edge Banding Strips

PVC edge banding is the most widely used material for sealing particleboard edges. It offers excellent cost-effectiveness, a wide range of colors and surface textures, and good flexibility, making it suitable for various mid-to-high-end furniture and kitchen cabinets.

PVC edge banding remains the top choice for furniture manufacturers and distributors due to its balance between price, performance, and visual appeal.

2. ABS Edge Banding Strips

ABS (Acrylonitrile Butadiene Styrene) edge banding is an eco-friendly alternative to PVC. It contains no chlorine or hazardous substances, providing superior toughness, low-temperature resistance, and enhanced hardness and wear resistance.

With a smoother surface and refined gloss, ABS edge banding is ideal for children’s furniture, premium cabinets, and medical or educational facilities where environmental standards are more stringent.

3. PP Edge Banding Strips

PP (Polypropylene) edge banding represents one of the most environmentally sustainable solutions for particleboard. It is 100% recyclable, highly resistant to heat, chemicals, and aging, and features a smooth, refined texture.

PP edge banding is particularly popular in European and American furniture markets, especially for outdoor furniture and brands that prioritize eco-friendly materials.

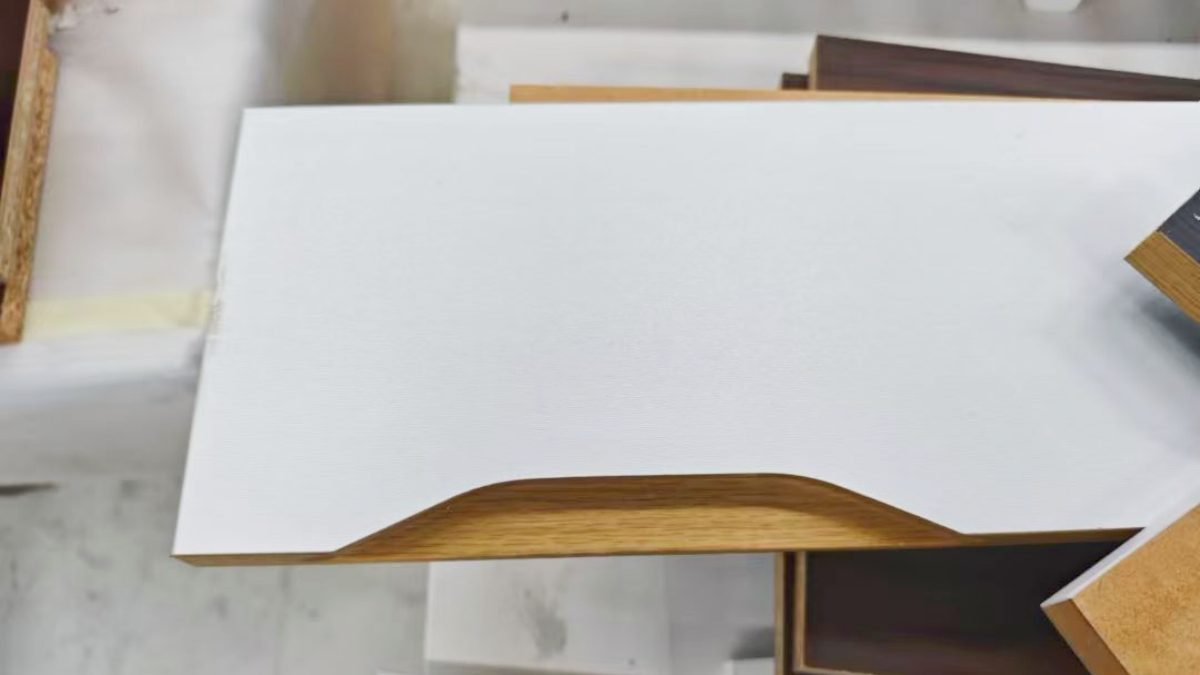

4. Melamine Edge Banding

Melamine edge banding is the most economical choice for sealing particleboard. It provides excellent color and texture matching with the board surface, offering a consistent, cohesive look.

This type is best suited for furniture manufacturers looking for low-cost, visually uniform solutions in large-scale production.

5. Acrylic Edge Banding

Acrylic edge banding gives furniture a modern and luxurious aesthetic. Its high-gloss, mirror-like finish creates a sleek and vibrant appearance, while offering outstanding scratch and wear resistance.

It is ideal for contemporary, minimalist, and high-end furniture designs, adding visual depth and premium appeal to particleboard panels.

How to Choose the Right Edge Banding for Particleboard

Selecting the right edge banding for particleboard furniture is essential for achieving durability, aesthetics, and cost efficiency. Whether you’re a furniture manufacturer, cabinet maker, or edge banding distributor, the following key factors will help you make the best choice:

1. Application Scenarios

Different furniture applications require different edge banding properties:

- Kitchen cabinets and bathroom vanities: Prioritize moisture resistance and oil resistance. PVC and ABS edge banding perform best in these humid environments.

- Office furniture and children’s furniture: Focus on eco-friendliness, safety, and durability. ABS and PP edge banding are the most suitable options.

- High-end furniture and commercial display cabinets: Emphasize appearance and scratch resistance. Choose acrylic or premium PVC edge banding for a glossy, refined finish.

- Low-cost or mass-market furniture: If cost control is the priority, melamine edge banding provides an affordable and efficient solution.

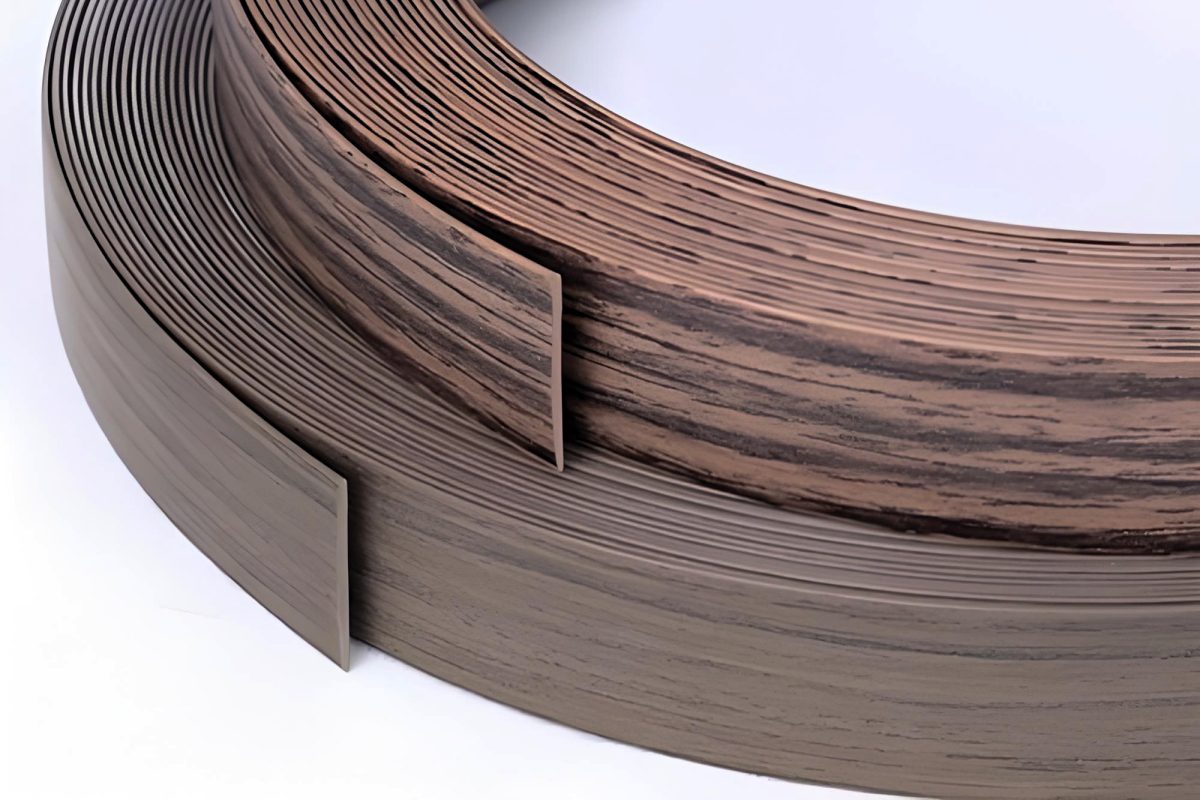

2. Size and Dimensions

Standard particleboard edge banding thickness ranges from 0.4 mm to 2.0 mm, while common widths include 16 mm, 18 mm, and 25 mm.

For best results, select an edge banding width slightly wider than the particleboard to ensure complete coverage and a seamless appearance.

3. Budget Considerations

Your budget determines the best material choice:

- High budget, high performance: Choose ABS or PP edge banding for superior strength, heat resistance, and environmental protection.

- Balanced cost and performance: PVC edge banding offers the best cost-effectiveness with a variety of colors and textures.

- Tight budget: Melamine edge banding is the most economical choice for large-scale production.

4. Processing Equipment Compatibility

Ensure that the selected edge banding material matches your edge banding machine type — whether manual, semi-automatic, fully automatic, or laser edge banding machine.

Different materials have specific requirements for hot melt adhesive temperature, feeding speed, and pressing pressure, so machine compatibility is critical to achieve the best bonding performance.

5. Overall Visual Effect

The color, texture, and gloss of the edge banding should coordinate with the particleboard surface to create a cohesive and high-quality look.

Choosing a matching or contrasting edge banding finish can enhance the furniture’s style, value, and market appeal.

How to Find Reliable Particleboard Edge Banding Strips in China

China is the world’s leading producer of furniture materials and a global hub for edge banding manufacturing. With its complete industrial supply chain, competitive pricing, and diverse product range, China is undoubtedly the best destination for sourcing particleboard edge banding strips.

Foshan Shengmei Decorative Materials Co., Ltd. is one of China’s top manufacturers of edge banding for particleboard, with over 15 years of export experience. We specialize in producing PVC, ABS, and PP edge banding strips, offering both standard and customized solutions to meet different production needs.

Our factory supports small-batch customization, provides fast delivery, and operates a professional testing laboratory to ensure that every roll of edge banding meets international quality standards for durability, flexibility, and color stability.

Conclusion

Although particleboard edge banding strips may seem like a small component in furniture manufacturing, they play a crucial role in defining furniture quality and longevity. Choosing the right edge banding not only enhances moisture resistance, durability, and environmental performance, but also elevates your brand image through superior craftsmanship and visual detail.

If you’re searching for high-quality particleboard edge banding strips for your furniture production line or hardware distribution business, contact Foshan Shengmei Decorative Materials Co., Ltd. today.

We offer free color samples, competitive prices, and professional support to help you find the perfect edge banding solution for your market.